Water everywhere, but not a drop to drink. However, Chaitanya Karamchedu is one thirsty teenager. An Indian-American student from Portland, Oregon, he has discovered a simple, cost effective and efficient technique that makes sea water potable.

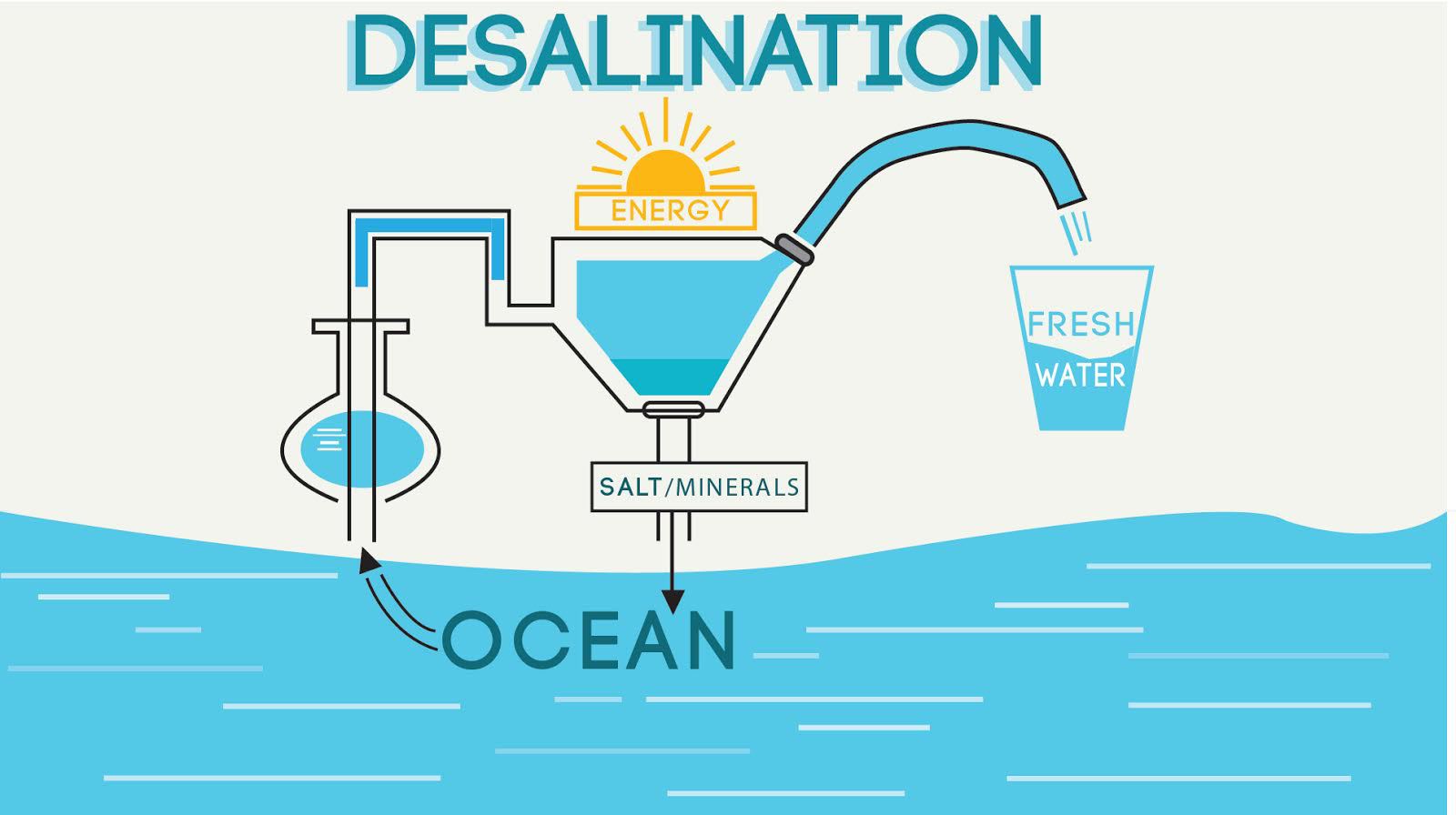

Chaitanya wanted to address the issue of clean water accessibility, which still remains elusive to many parts of the world. He believed that the best access to water is the sea. However, since more than two thirds of the planet’s water is in the Oceans and full of salt, it remains unfit for human consumption. Isolating drinkable water from the ocean in a cost effective way is a problem that has stumped scientists for years. He says, “Scientists looked at desalination, but it’s all still inaccessible to [some] places and the infrastructure would cost too much to implement on a large scale.”

That thought led him to his school’s science lab where he realized that sea water is not fully saturated with salt. He figured that all the research until now, focused on 10% of water that’s bonded to the salt in the sea. Chaitanya addressed the problem by experimenting on the remainder 90% of the water that is free from salt bonds. Then, using a highly absorbent polymer, Chaitanya was able to discover a cheaper method effective way to remove salt from ocean water and turn it into fresh water.

Using superabsorbent hydrophilic polymers, with no external energy, under room temperature and pressure, Chaitanya was able to produce drinkable water which stands WHO standards for potable water. Based on saponified starch-grafted-polyacrylamide’s hydrophilic properties, he was able to create a hydrogel to separate freshwater from seawater, then separated hydrogel from the brine, dewatered the gel, which resulting in aqueous sulfuric acid and then recovered fresh water from the aqueous solution.

Chaitanya’s method to desalinate water required no thermal or electrical energy and the extracted water was comparable to fresh water with an average conductivity of 306.32 µS/cm, comparable to the conductivity of 200 µS/cm for the reference distilled water used. It involves virtually no cost for pre-treatment and post-treatment and it is amenable for small scale use as well. Mass and conductivity analysis showed that the extracted water had a total dissolved solids concentration of 513 mg/L, well within WHO standard at <600 mg/L, compared to 35,000 mg/L for seawater.

The sodium concentration was 25.8 mg/L, compared to 10,500 mg/L for seawater and that of chloride was 36 mg/L, compared to 19,000 mg/L for seawater. The relevant EPA secondary concentration levels (aesthetic standards) for sodium is 20 mg/L and for chloride is 250 mg/L. The process yielded over 70% of fresh water and also produced a commercially useful fertilizer, CaSO4, as a byproduct.

Chaitanya Karamchedu has already won a $10,000 award from the US Agency for International Global Development at Intel’s International Science Fair and MIT’s TechCon Conference has provided funds for him to continue his research.